FILTERATION

Filtration is the process of removing suspended impurities and turbidity from water. ACE AQUA TECHNOLOGIES offers all media, cartridge & membrane filtration technologies.

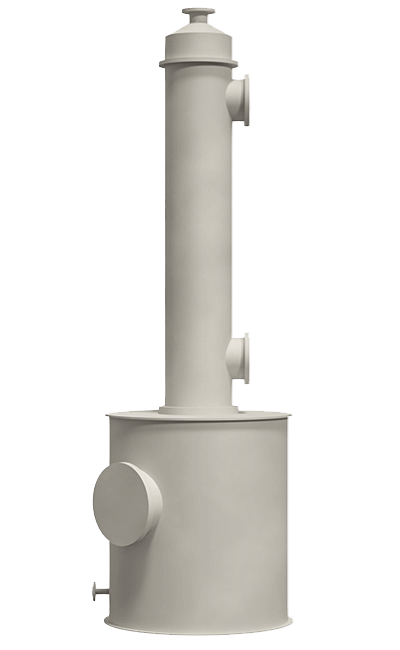

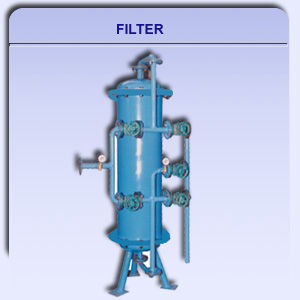

MEDIA FILTERATION is used as a first step in most water purification systems to remove particulate matter.

Any given filter revolves on the media known as bed to function efficiently. The supporting bed consists of pebbles which hold the media. The vessel has besides the above, distribution and collecting systems and is connected externally to frontal pipelines and valves. The pipe lines function as the system letting into the vessel untreated water, letting out of the vessel the filtrate also for back wash and rinsing. Pressure indicators reveal the given condition of the media to facilitate backwash timing.

We are so flexible that any and every conceivable user requirement is

taken into critical consideration: thus you have a range of down flow, up-flow, vertical and horizontal filters – you name it we have it.

Simple, easy to install, task oriented, user friendly MEDIA FILTERS cater to various end user need.